The Craftsman Hydrostatic Transmission Problems is a common problem for lawn tractor owners. The problem is that the hydrostatic transmission fluid leaks out of the hydrostatic pump, causing the tractor to lose power and eventually stall.

This can be a very frustrating problem, as it can be difficult to diagnose and repair.

There are a few things that you can do to try to fix this problem, but it is often best to just replace the entire hydrostatic transmission.

If you’re a Craftsman owner with a hydrostatic transmission, you may have experienced some problems. Here are some common issues and how to fix them. Leaks: If your transmission is leaking, it’s likely due to a bad seal or gasket.

You can try replacing the seals or gaskets, but if that doesn’t work, you may need to replace the entire transmission. Noise: If your transmission is making noise, it could be due to low fluid levels or an internal problem. Check the fluid levels and add more if needed.

If that doesn’t solve the problem, you may need to take it to a mechanic for further diagnosis. Slipping: If your transmission is slipping, it could be due to low fluid levels, worn parts, or debris in the system. Check the fluid levels and add more if needed.

You may also need to flush the system and/or replace worn parts.

Craftsman Hydrostatic Transmission Problems fix

Craftsman Hydrostatic Transmission Problems are-

- Sloppy and intermittent shifting Problem,

- Poor engine response to go-pedal input Problem,

- Fluctuating RPM during transmissions Problem,

- Slipping or no sync on the gear shifts Problem,

Fix

To fix the Sloppy and intermittent shifting Problem, following below.

- Release the screw on the shift lever and remove it from the transmission (you can do this without removing the transmission gear cover).

- Remove the swing-arm pivot nut, which is located under a small cover situated beneath the engine.

- Move your transmission drain bolt to its mid-position and remove it from the transmission case.

- Replace your starter with a new one (you should not have to do this if you have an old one).

To fix the Poor engine response to the go-pedal input Problem, the following is below.

- Remove the air filter housing, located under the air cleaner box on the left side of the engine. Remove the four bolts which hold the filter in place, but do not remove the air filter itself or its mounting bracket.

- The shift lever pivot bearing (shown in red) is pressed against a large bearing called an “oil scraper”. Retain the paper clip and remove the pivot bearing from its balk with a pair of pliers.

- Remove the left-side engine cover, which is held in place by four bolts. The cover should now be loose enough to slide off of the engine. Remove any dirt or carbon deposits that may have attached themselves to the cover when it was first put on, as this will make it difficult for you to reassemble it in precisely the same way.

To fix Fluctuating RPM during transmissions Problem, I have for you below.

- Remove the air filter housing, located under the air cleaner box on the left side of the engine, as described in the previous section.

- After removing the oil scraper bearing pinion, yank out all four of its rollers (shown in red). These are located in a recess near each corner of its square base. Use a large screwdriver to pry them out gently and push them into place as you remove them.

To fix the Slipping or no sync on the gear shifts Problem, the following is below.

- The problem is more likely to occur if you tow a trailer often with your hydrostatic transmission. Before you even get out of bed, back up to the trailer and plug into it. If your truck has a problem shifting, and you pull forward to line it up with the RV, then back up to unplug, the transmission will be in low range when you try to perform a shift up into the drive.

- The main transmission shaft is a V-shaped blade and has a large bearing on its bottom end that rides in the transmission case. As the bearing ages, it will allow the shaft to rock back and forth, which can cause shifting problems. If you have tried everything else, but you still have problems with shifting, you may need to replace the bearing and seal assembly.

What Causes Hydrostatic Transmissions to Fail?

There are many potential causes of hydrostatic transmission failure. The most common include:

Read More About Kubota L3901 Problems

1. Debris in the system:

Over time, debris can build up in the hydraulic fluid, causing clogs and blockages. This can prevent the proper flow of fluid and lead to transmission failure.

2. Leaks:

Even small leaks can cause major problems for hydrostatic transmissions. Fluid leaks can lead to loss of pressure, which can cause the system to fail.

3. Wear and tear:

Like any other mechanical system, hydrostatic transmissions will experience wear and tear over time. This can cause parts to break or fail, leading to transmission failure.

4. Improper maintenance:

Hydrostatic transmissions require regular maintenance in order to function properly. If they are not properly maintained, they are more likely to fail prematurely.

How Do You Add Fluid to a Craftsman Hydrostatic Transmission?

If your Craftsman hydrostatic transmission is low on fluid, you can add more by following these steps:

- Park the tractor on a level surface and set the parking brake.

- Remove the dipstick from the transmission and wipe it clean with a rag.

- Insert the dipstick all the way into the transmission fill hole.

- Slowly pour transmission fluid into the fill hole until it reaches the full line on the dipstick. Do not overfill.

- Re-insert the dipstick and screw on the cap/plug tightly to avoid leaks.

How Does a Craftsman Hydrostatic Transmission Work?

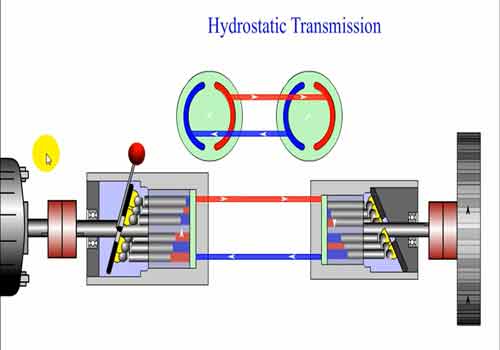

A hydrostatic transmission is a type of fluid power transmission that uses pressurized hydraulic fluid to power the drivetrain of a vehicle.

It is similar to a hydraulic system, but with some key differences. In a hydrostatic transmission, the hydraulic fluid is not confined in a closed system like it is in a traditional hydraulic system.

Instead, the fluid is allowed to flow freely between two chambers separated by an adjustable orifice. This design allows for infinitely variable speed control and makes hydrostatic transmissions more efficient than traditional hydraulic systems. The heart of a hydrostatic transmission is the pump/motor unit.

This unit contains two chambers separated by an adjustable orifice ( throttling valve). One chamber houses the fixed displacement pump while the other contains the variable displacement motor. The pump draws the fluid from a reservoir and pumps it into the motor chamber.

The motor then uses this pressurized fluid to drive the output shaft. The speed of the output shaft can be controlled by changing the size of the orifice between the pump and motor chambers.

A larger orifice will allow more fluid to flow into the motor chamber and increase speed, while a smaller orifice will restrict flow and decrease speed.

The direction of travel can also be reversed by reversing the direction of flow through the pump. Hydrostatic transmissions are used in many applications where precise control over speed and direction is required such as construction equipment, agricultural machinery, material handling equipment, and robotics.

Read Also Mahindra Emax 22 Problems

Why Won’t My Hydrostatic Mower Won’t Move?

There are a few potential reasons why your hydrostatic mower won’t move. First, check the transmission fluid level and add more if needed. Next, make sure the drive belt is not broken or loose.

Finally, inspect the hydrostatic pump for any leaks or damage. If all of these things check out, then it’s likely that the problem is with the hydrostatic motor itself and you will need to take it to a repair shop for further diagnosis.

Craftsman Hydrostatic Transmission Adjustment

If your Craftsman lawn tractor isn’t moving as it should, the hydrostatic transmission may need adjustment. This is a relatively simple process that you can do yourself, and it only takes a few minutes. First, check the oil level in the hydrostatic transmission.

If it’s low, add oil until it reaches the full line on the dipstick. Next, locate the two fill plugs on the side of the transmission. Remove them and check that the fluid level is at least halfway up to the top of each plug hole.

If necessary, add transmission fluid until it reaches this level. Finally, replace both fill plugs and tighten them securely. With these steps, your Craftsman lawn tractor should be back to running smoothly again.

How to Tell If Hydrostatic Transmission is Bad

If your lawn mower or other small engine equipment is having trouble moving forward, or if the transmission is making noises, it may be time to check the hydrostatic transmission.

Here are some ways to tell if the hydrostatic transmission is bad:

- The equipment isn’t moving forward or backward as it should.

- The transmission makes noises that it didn’t make before, such as grinding or whining sounds.

- There’s leaking fluid around the transmission area.

- The steering feels different, especially when you turn sharply.

Craftsman Hydrostatic Transmission Fluid Change

If your lawn tractor has a Craftsman hydrostatic transmission, it’s important to change the fluid regularly. Here’s how to do it:

- Park your tractor on a level surface and turn off the engine. Remove the key from the ignition.

- Raise the hood of the tractor and locate the hydrostatic transmission fluid dipstick. It will be located near the front of the engine, on the side of the transmission housing.

- Clean off the dipstick with a clean cloth or paper towel, then reinsert it into the dipstick tube.

- Pull out the dipstick again and check the fluid level on it. The fluid should be at or just below the “Full” mark on the dipstick (see photo). If it’s low, add hydrostatic transmission fluid until it reaches that level; if it’s high, remove some until it does reach that level (you can use a turkey baster for this).

- Replace any parts you removed (dipstick, cap/lid) and close up the hood of your tractor. You’re now ready to mow again.

Hydrostatic Transmission Troubleshooting

In a hydrostatic transmission, fluid is pumped through a system of valves and chambers to control the speed and direction of a driven shaft.

The fluid pressure created by the pumps drives the gears in the transmission. If your hydrostatic transmission is not working properly, there are several things you can do to troubleshoot the problem.

First, check the level of hydraulic fluid in the reservoir. If it is low, add more hydraulic fluid until it reaches the full line on the dipstick. Next, check for leaks in the system.

Look for any wet or oily spots on hoses or fittings. If you find a leak, replace the damaged part. If your hydrostatic transmission is still not working properly, you may need to adjust the relief valve.

This valve controls how much pressure builds up in the system. To adjust the relief valve, consult your owner’s manual or contact a qualified technician.

Read More About Cub Cadet Rzt 50 Problems

Craftsman Hydrostatic Transmission Slow Reverse

A hydrostatic transmission is a type of power transmission that uses fluid pressure to provide power to a machine. A hydrostatic transmission typically consists of a pump, a motor, and a control valve, and can be used to provide variable speed and torque control.

Hydrostatic transmissions are often used in agricultural and construction equipment, as well as in some types of industrial machinery.

Craftsman hydrostatic transmissions are known for their quality and durability. However, like all mechanical components, they can experience problems from time to time. One common issue that can occur with Craftsman hydrostatic transmissions is the slow reverse.

This problem can be caused by several different factors, and it is important to diagnose the root cause before attempting to repair the transmission.

One possible cause of slow reverse in a Craftsman hydrostatic transmission is low fluid level. The transmission relies on hydraulic fluid to operate, and if the fluid level gets too low, the transmission may not be able to generate enough pressure to move in reverse.

Another possible cause of slow reverse is air in the system. Air bubbles can form in the hydraulic fluid, which can reduce the overall pressure in the system and make it difficult for the transmission to move in reverse.

Finally, worn or damaged seals or gaskets may also cause slow reverse by allowing hydraulic fluid to leak out of the system.

If you are experiencing slow reverse in your Craftsman hydrostatic transmission, check the hydraulic fluid level first. If the fluid level is low, add more until it reaches the full mark on the dipstick.

If adding hydraulic fluid does not solve the problem, then you will need to bleed air out of the system using a procedure called “purging.”

Once you have bled the air out of the system, check all seals and gaskets for leaks and replace any that are damaged or worn out.

Hydrostatic Transmission Slipping When Hot

If you have a lawn tractor with a hydrostatic transmission, you may have experienced slipping when the transmission gets hot. This is a common problem that can be caused by several different factors. One possible cause is low fluid level.

The hydrostatic transmission fluid should be checked regularly and topped off as needed. If the fluid level is low, it will cause the transmission to slip when it gets hot. Another possible cause is dirty or contaminated fluid.

Over time, the hydrostatic transmission fluid can become dirty and need to be replaced. If the fluid looks dark or cloudy, it needs to be replaced. Contaminated fluid can also cause the transmission to slip when it gets hot.

A third possible cause is worn gears. The gears in the hydrostatic transmission can wear out over time and this will cause the transmission to slip when it gets hot. Gears can also break, which will also cause slipping.

Craftsman Lawn Tractor Transmission Problems

If you own a Craftsman lawn tractor, you may eventually experience transmission problems. The most common issue is when the transmission slips or loses power. This can be caused by a variety of factors, including low fluid levels, worn-out gears, or a faulty clutch.

If you notice your transmission slipping, it’s important to take action right away. Otherwise, you could end up damaging the engine or other parts of the tractor. First, check the transmission fluid level and add more if needed.

Next, inspect the gears for wear and tear. If they’re excessively damaged, you’ll need to replace them. Finally, check the clutch for any issues.

If it’s not functioning properly, it will need to be replaced as well. Transmission problems can be frustrating, but fortunately, there are ways to fix them. By taking care of these issues as soon as they arise, you can keep your Craftsman lawn tractor running smoothly for years to come.

Specification

| Model | Kohler VC730 |

| Type | 4-cycle gasoline engine |

| Cylinder | 2 |

| Speed | 2800rpm |

| Fuel system | Carburetor |

| Fuel tank | 5L |

| Spark | RC12YC |

| Ignition System, | Electronic |

| Air cleaner | Paper elements |

| Low speed | 1500rpm |

| Piston | 725 |

| Cooling | Air intake |

Do craftsman lawn tractors have transmission problems?

Yes, they do. And it’s not because you’re old; it’s because your transmissions are electrohydraulic. Craftsman models, like ALL other mowers, consider the transmission to be under the hood.

They are built with a hydraulic pump and a gear shift housing that goes under the hood. The transmission shaft is attached to one end of this gear shift housing (the W) by means of a keyed shaft.

What are the most common tractor hydrostatic transmission problems?

They’re not designed to last very long. They actually only last about 5-10 years. The pump and gear shift housing are not the parts that wear out; it’s the case itself.

This is because when you’re shifting gears, or even just backing up, you often apply a lot of pressure to different areas of the case because it’s a hydraulic transmission.

Why does my Craftsman tractor stop without any signal?

A lot of times it’s your gear shift cables. There are usually two cables. One goes from the gear shift housing to the ignition switch, and the other one goes from the switch to the hydraulic pump on the transmission shaft.

Inspect them for fraying and hardening, for example. They normally last about 3-5 years before they break off completely, often causing your transmission to stall in neutral or park (you can’t get it into the drive).

How do you check the transmission fluid on a craftsman tractor?

You have to remove the drain plug that’s under the bottom of the transmission just like you do on your car. It takes a little bit of skill to do it, but it’s not too tough.

If you can’t get it out, then check the fluid level first. It should be about 1-2 quarts below the top of the filler neck (the neck is where it goes under the engine). After you’ve done that and filled it up, then go ahead and try to remove the drain plug again.

FAQ

Do hydrostatic transmissions need maintenance?

Maintenance is pretty simple. You need to use a properly sized fluid every couple of years. Try to use one which is compatible with your models, and try not to overfill it.

Can you use hydraulic fluid in a hydrostatic transmission?

Yes, you can use hydraulic fluid in a hydrostatic transmission. The only problem is that it’s a good idea not to. You may get the transmission shifting okay, but your engine may experience some oil consumption because the fluid is failing to clean itself up.

Is hydrostatic oil and hydraulic oil the same?

Yes. Hydrostatic oil and hydraulic oil are the same. Hydraulic oil is a type of hydrostatic oil used mostly for fluid power systems rather than for hydrostatic transmission.

Is hydrostatic better than automatic?

It’s a matter of preference. The automatic transmission requires some work on your part. It requires shifting, even though it has a more powerful engine and more power than the hydrostatic transmission.

Craftsman hydrostatic transmission troubles

Conclusion

If you own a Craftsman hydrostatic transmission lawn tractor, you may eventually experience Craftsman Hydrostatic Transmission Problems with it. The most common issue is that the transmission may start to slip, which can cause the lawn tractor to lose power or even stall.

In some cases, the problem may be caused by a leak in the hydrostatic fluid system, which will need to be repaired.

Other potential causes of transmission problems include a broken drive belt or damaged pulleys. If you’re experiencing any type of problem with your Craftsman hydrostatic transmission lawn tractor, it’s best to take it to a qualified repair shop for diagnosis and repairs.